… enabling floating wind™

swift

(Strategic Wind Infrastructure)

Inspired by the fixed offshore wind sector’s ability to scale-up successfully, Encomara’s approach mirrors its strategy by enabling installation which is independent of sea state, enables high-volume manufacturing of standardised hardware, and allows the pre-installation of all marine and subsea interfaces.

Following a significant research and development investment, the firm’s pioneering SWIFT (Strategic Wind Infrastructure), uses the company’s patented SQUID to provide a comparable level of installation efficiency and cost savings for the floating wind sector.

The technology allows for the pre-installation of all marine hardware, enabling rapid installation and earlier first power from multiple turbines.

SQUID enables STRATEGIC WIND INFRASTRUCTURE (SWIFT), which is:

- High Tension Deck Operations and risks to personnel are reduced

- High Thrust/Tension Vessel Ops in vicinity of FOWT & moorings are reduced

- Fully pre-installed mooring and inter-array cable (IAC) system:

- Reduces Vessel/FOWT collision exposure

- Facilitates open-water weather-vaning

- Mitigates consequences of Dynamic Positioning failure

- Fewer vessel days at lower engine intensity reduces statistical risk exposure

- Fewer vessel days, higher operability and optimised weathervane capability result in significantly reduced:

- Green house gas (GHG) emissions

- Atmospheric noise

- Subsea noise

- General Marine Mammal disturbance

- Supporting the pre-installed moorings & power cables significantly reduces benthic disturbance

- Allows pre-installed and pre-commissioned mooring & inter-array cable systems

- Superior operability equates to reduced weather downtimes

- Shorter FOWT hook-up duration

- No post FOWT hook-up cable pull-in schedule exposure

- 42% more FOWTS installed per season*

- Pre-installation, superior operability, faster FOWT hook-up provide:

- Fewer vessel days overall

- Fewer vessels in the marine spread

- Reduces pressure of vessel market rates

- Less fuel consumption

- Less offshore time / higher productivity for FOWT Crews

- Shorter quayside lease duration at Capex Phase

- Reduced Project duration and management cost

- These benefits are repeated for T2P, Re-Power and Decom Phases

- Faster installation rate increases Yield by 27%* during ramp-up

- Circuit continuity increases yield during Tow-to-Port (T2P) events

- Life-of-Array impact of ~2.5%* Higher Yield (~ 3.3 TWh)

- Faster start-up & T2P continuity boost NPV substantially

*Based on a generic 1.2GW Scotwind development comprising 16 strings of 5 x 15MW FOWTs

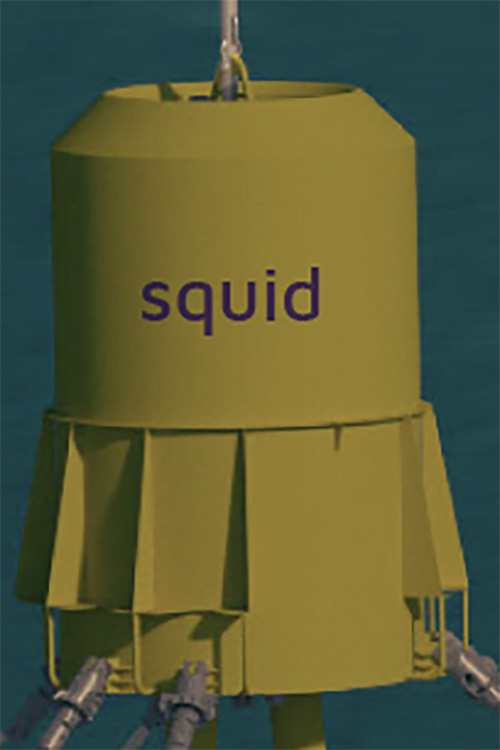

squid

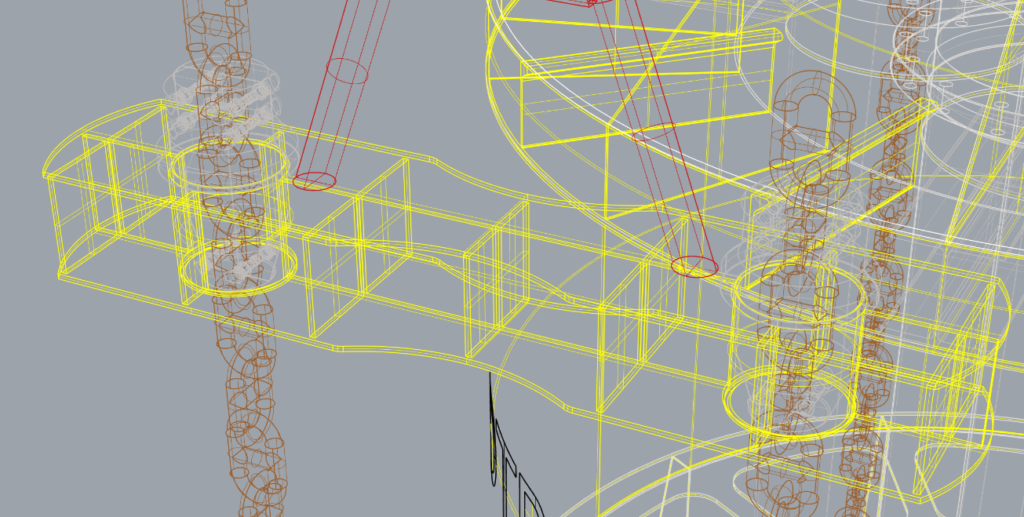

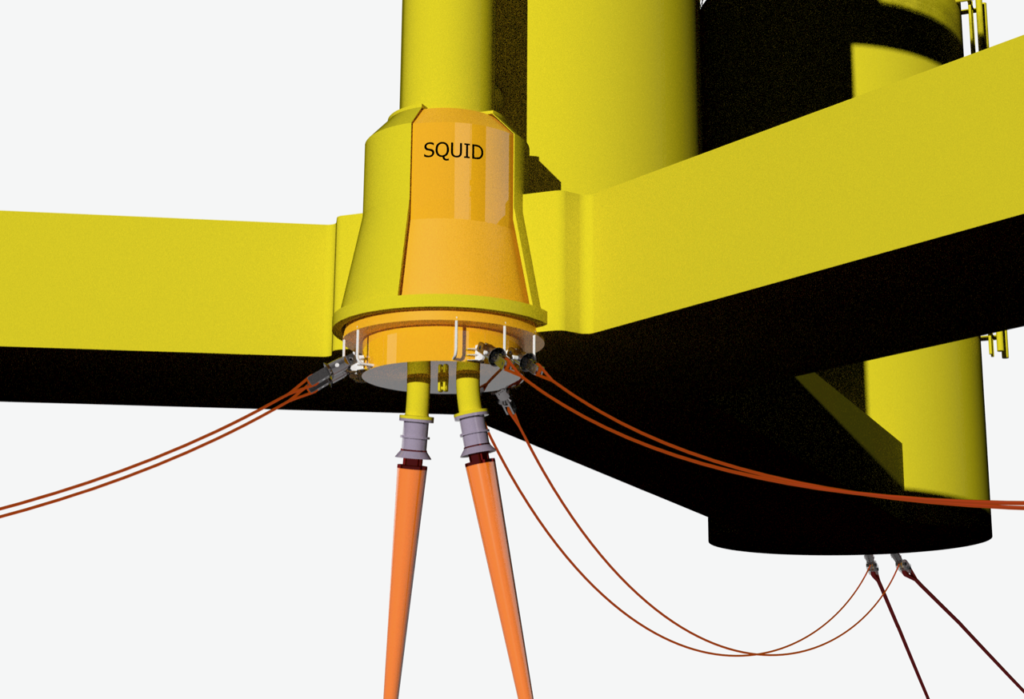

SQUID is the enabling product which delivers the benefits of SWIFT (Strategic Wind Infrastructure). It is a universal, pre-installed mooring & power cable interface which is compatible with a variety of hull designs.

SQUID integrates all associated marine hardware components, such as power cables and connectors, mooring lines and anchor interfaces to provide a rapid and simplified “Plug to Power”‘(P2P) capability. It is suspended mid water and holds power cables & moorings in a similar configuration to that when connected, ensuring high operability & reduced risk of damage to hardware and the seabed. This allows developers to pre-install 100% of subsea & marine hardware in advance of FOWT deployment and maximise the pre-commissioning similar to fixed wind, prior to the turbine arrival. This significantly reduces the direct CAPEX and duration of Floating Offshore Wind Turbine (FOWT) installation. Additionally, by solving the Tow to Port (T2P) challenge, the SQUID delivers similar cost and duration reductions during the operational, re-power and decommissioning phases.

SQUID significantly reduces hazardous marine operations and deck operations by maximising safer ROV based operation under the water. During FOWT deployment the SQUID is pulled into a dedicated J-tube in a single lift which enables rapid installation of multiple FOWTs. The J-tube configuration is ‘agnostic’ to various hull interface configurations.

SQUID can be installed in a wide range of sea states, which supports a longer weather window for operations with minimal intervention downtime, reducing standby vessel support and helping to lower the carbon footprint of offshore wind projects.

SQUID is aligned with operators and developers ESG strategies and the industry’s increasing commitment to sustainability and net zero.

strategic consultancy

Our Team and contact network has extensive experience in offshore equipment, asset development, project execution and market knowledge. This spans exploration, marine, fixed and floating wind and places us in a strong position to support and work with developers to common goals.

- System installation and in-place analysis, scheduling, costing, weather & risk analysis

- Project evaluation, supplier assessment, due diligence, insurance & expert witness work

- Vessel, equipment and facility development and market insight

- Mooring and anchoring systems – all components, depths, environments.

- Static & dynamic power cable systems, including ancillaries.

- Offshore control and ESD systems

- Floating structures

- Offshore construction

- Marshalling & logistics

- Marine operations